SEACAP

Why SEACAP?

SEACAP

is environmentally friendly, durable and its robustness is perfectly adapted to the violent and sometimes extreme environment of ocean exploitation.

Production

can be converted in-situ and according to needs, into electricity or H2.

Related industrial activities can be associated from the electricity produced (desalination, microalgae, hydrogen, aquaculture, secondary recovery, etc.).

Installation

can be quickly mobilized and repositioned. The platforms are also easily recyclable at any time and obviously at the end of the equipment's life.

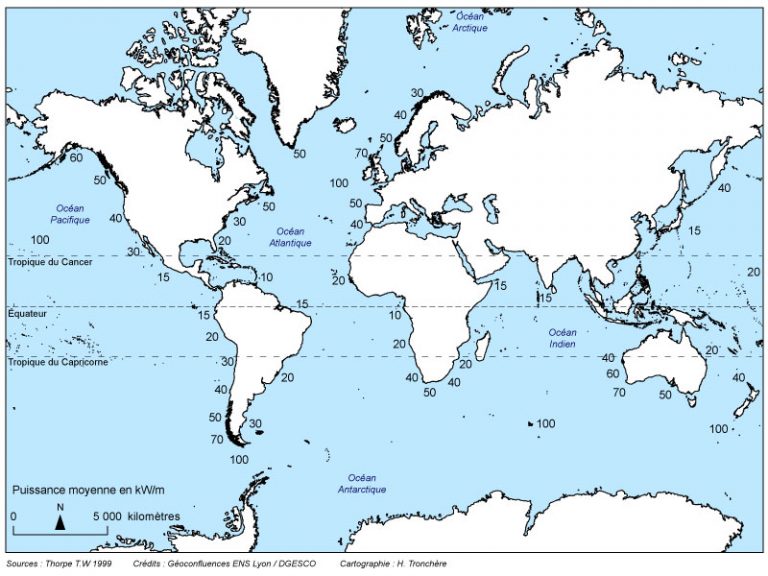

Ocean waves

is universally available and of variable power according to the latitudes. Its exploitable production potential is 2,000 to 8,000 TWh/year worldwide .

(1 TWh = 1 million MWh)

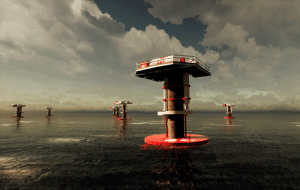

The modular SEACAP platform.

SEACAP, is a simple and robust marine energy capture and conversion (PTO) system. Disruptive, although essentially based on known technological modules, proven in the offshore oil industry for decades (platforms operated in very difficult environments).

The heart of the energy production system is made up of Direct Drive Switched Reluctance Linear Generators (AMSRM), controlled by latest generation electronics. This constitutes a considerable advance in terms of renewable energy production, performance, security and therefore ultimately cost (LCOE) of the carbon-free energy necessary for the energy transition.

The design of the platforms also makes it possible to produce green hydrogen in situ and thus break free from the intermittence of marine resources or, alternatively, to supply the clean energy mobility, currently consuming hydrocarbons. Likewise, many other industrial activities, in addition to highly polluting heavy land and sea transport, could benefit from this production of hydrogen.

It is notable that, in France in particular, electricity consumption (540 TWh in 2019) is 70% of hydraulic and nuclear origin. It is therefore already very low carbon (even if this latest technology, nuclear, induces other very important problems, from heavy investments, safety of installations, transport of hazardous materials, the availability of water or its discharge temperature, to, and not the least, long-lived wastes, etc.).

However, in France, electricity is only about 25% of the total energy consumption.

Therefore, there is still a great deal of effort to be made on the other 75% (or around 140 million TOE!),

which largely come from fossil sources, of which, 44% for oil and 20% for gaz.

Essentially for industry and road, sea and air transport, where hydrogen can and is already starting to provide solutions.

SEACAP

High-performance multifunction platforms

Structure

Steel or concrete monopile, on an anchored gravity or suction base that can be subjected to the most extreme conditions. Equipped with a float, activator of linear generators, the captured energy of which can be directly exploited on the deck or evacuated to the terrestrial network.

Electronic power controller

State-of-the-art electronics for real-time control of the resource and generators as well as the level and type of production chosen.

Exploitation is controlled by a Scada system from the coast, making offshore interventions very infrequent.

Wave energy fields

Rows of Seacap platforms of sizes and powers adjustable to your projects and in all environmental conditions.

Typically a field will be studied for a total power of 200 to 300 MW able to operate on average 4000 h/year.

Linear generators

Innovative and efficient switched reluctance linear generators to achieve a high level of density and high continuous and maximum force. In the process of being finalized within the framework of the “H2020 Seatitan” project bringing together several European partners, tests are scheduled for the near future.

Installation

By light naval means.

A floating version similar to a SPAR type column for great depths will be derived later.

Float (activator)

Size and weight adjustable according to the sites and their environmental characteristics.

SEACAP

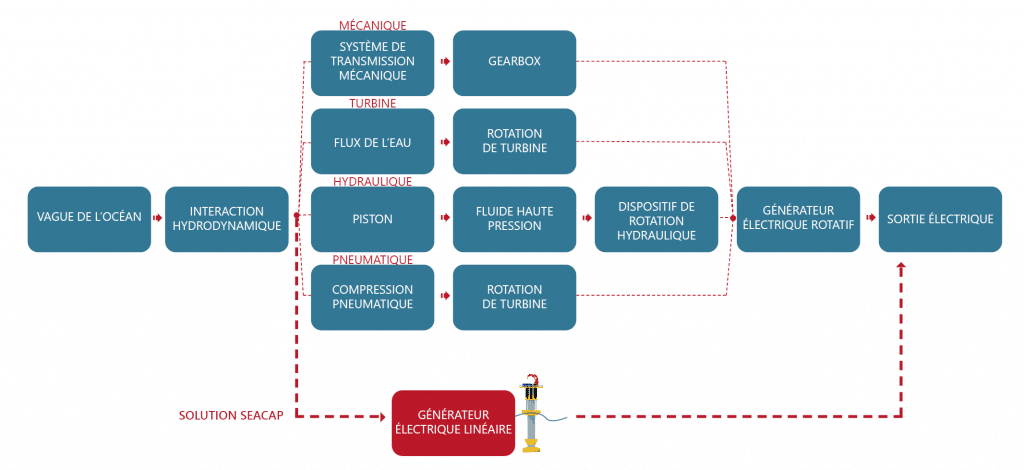

Innovative generators

Modular generators easily installed, or replaced in the event of scheduled or accidental maintenance, by standard exchange and without excessive downtime.

Without unnecessary mechanical transfers, reducing the power and costly in maintenance.

Direct production from the swell to the electrical outlet

A new generation of innovative and efficient direct drive, switched reluctance generators providing a higher force density than rotating machines, without the use of permanent magnets.

SEACAP

Operational management

Economical maintenance thanks to its Modularity and Scheduled maintenance

continuous proactive surveillance by a Scada network operated from the coast

Reinforced safety for maintenance operators and equipment